I. Use and characteristics:

The thick adhesive adhesive tape for oil transportation is a new type of antiseptic adhesive tape developed on the basis of the traditional thin polyethylene antiseptic tape. The base material is high and low density synthetic polyethylene film, and the adhesive layer is high viscosity thermoplastic modified butyl self-adhesive anti-corrosion adhesive, supplemented by a layer of anti-adhesion isolation film. It can be widely used in oil, natural gas, chemical industry, urban construction of water supply and drainage, oil and gas, gas transportation steel pipeline and steel buried storage tank of external anticorrosion and repair engineering. Is a kind of latest pollution-free, non-harmful environmental protection anti-corrosion material, compared with the traditional anti-corrosion adhesive tape, has the following advantages:

1, strong viscosity and can achieve self-fusion, waterproof, gas penetration, good sealing.

2. High electrical insulation, excellent aging resistance and stability, strong uv radiation resistance.

3, has the ability to resist soil stress damage, strong impact resistance.

4. Single-layer winding of adhesive tape can achieve the ordinary or enhanced anticorrosion required by SY/T0414-2017 standard. The traditional adhesive tape needs multi-layer winding, which reduces the influence of human factors on anti-corrosion quality and reduces the construction cost.

5, simple construction, fast speed, no curing time, manual and mechanical operations can shorten the construction period.

6, low cost, no pollution and waste.

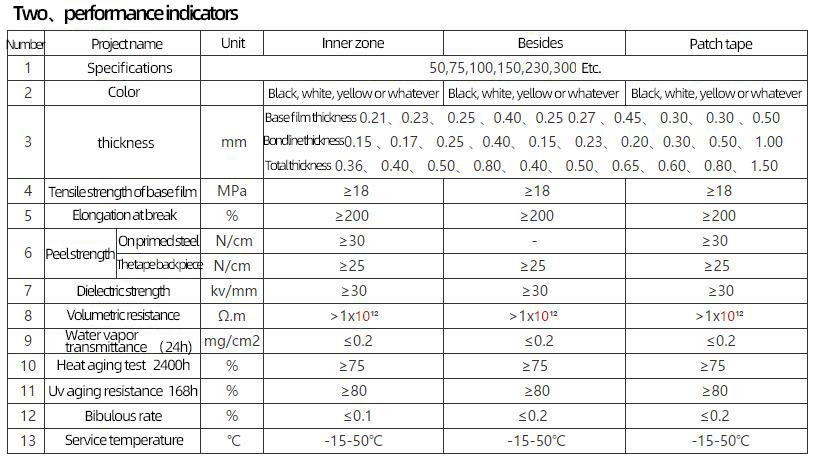

Thick rubber polyethylene antiseptic tape by the national professional detection, the indicators are much higher than SY/T0414-2017 standard requirements, fully in line with the American ANSI/AWWAC209-00 and NACEMR0274-95 indicators, is the current antiseptic cold tape in the most economic, the most environmentally friendly products, has a high value of promotion and application。

Three, construction steps:

Derusting > Primer > Adhesive tape > EDM > peel strength test.

1. Rust cleaning pipe:

The surface of steel pipe must be treated, and the surface treatment quality shall reach Sa2 or St3 level specified in GB/T8923-88 "Corrosion grade and Rust Grade of Steel Surface before Painting", and the dust on the surface shall be removed.

2. Priming:

Before primer coating, stir evenly in the container, apply primer on the surface of the steel tube qualified for rust removal and dust removal, so that it forms a uniform film, until the primer surface dry (hand touch not stick) can be wrapped (generally need 3-5 minutes). The amount of bottom paint is generally 80-100g/㎡.

3. Anti-corrosion tape:

With appropriate mechanical or manual tools, wrap the tape on the coated pipe according to the lap requirements, the tape tension can be 10-20N/cm. The length of the lap between the beginning and end of the adhesive tape shall not be less than 1/4 of the circumference of the tube, and shall not be less than 100mm. Each winding circle shall be parallel and shall not be twisted or wrinkled.